If we look at Product Information Management (PIM) in manufacturing there are many good solutions for taking care of the End-to-End needs within your organisation. The aim is to gather the product information that exist within your organisation in various silos, have one trusted place for all this information and being able to publish this information in a consistent way in your own sales channels.

However, product information does in many cases not live just within your organization. In most cases, it lives in a business ecosystem of you as an manufacturer and distributors, merchants and large end users.

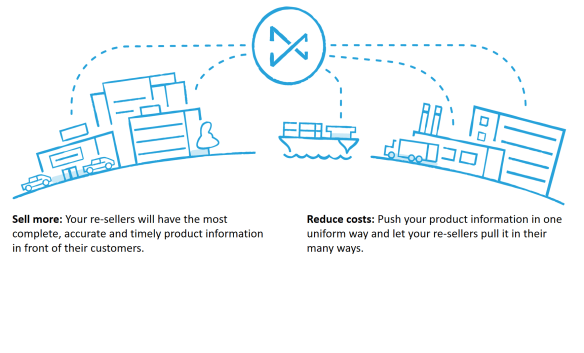

Therefore we need an End-to-End solution for product information exchange (product data syndication) that encompasses the path from you as a manufacturer through distributors to merchants and large end users and in some cases the way back.

Our concept, using emerging technologies within Product Data Lake, will free you from applying many different solutions to providing product information to your re-sellers. You will avoid errors. You will be able to automate the processes and you will be easy to do business with in the eyes of your trading partners.

The people who will use your products want to get complete product information when making the buying decision wherever they are in the supply chain.

You can join the business ecosystem oriented End-to-End solution for product information. Please find some more information about Product Data Lake here.

If you want to know more: Get in contact here:

If you want to know more: Get in contact here:

The title of this blog post is the title of, in my rapid eye movements, one the best albums ever:

The title of this blog post is the title of, in my rapid eye movements, one the best albums ever:  This approach seems to work if you are bigger than your trading partner. And many times one will be bigger than the other. But unless you are very big, you will in many cases not be the biggest. And in all cases where you are the biggest, you will not be seen as a company being easy to do business with, which eventually will decide how big you will stay.

This approach seems to work if you are bigger than your trading partner. And many times one will be bigger than the other. But unless you are very big, you will in many cases not be the biggest. And in all cases where you are the biggest, you will not be seen as a company being easy to do business with, which eventually will decide how big you will stay. The Competition and The Neutral Hub

The Competition and The Neutral Hub